Sticky-back Thermal Lamination Pouch Film With Removable Backing

Product Description

Sticky-back thermal lamination pouch film is a specialized type of lamination film that features a self-adhesive backing, making it suitable for a wide range of applications. This unique feature allows it can be easily affixed to smooth surfaces without the need for additional adhesives. It is specifically designed for convenience and versatility.

EKO is China’s leading pre-coated film manufacturer, and our products are exported to more than 60 countries. After more than 20 years of innovation, we have obtained 21 patents. As one of the pioneer manufacturers and researchers of BOPP pre-coated films, we played a key role in setting the industry standard for pre-coated films in 2008.

After sales service

Please let us know if there's any problem after receiving, we will pass them to our professional technical support and will try to help you to solve.

If the problems are still unresolved, you can send us some samples(the film, your products which have problems with using the film). Our professional technical inspector will check and find the problems.

Storage indication

Please keep the films indoor with cool and dry environment. Avoid high temp, moist, fire and direct sunlight.

It's best used within 1 year.

Packaging

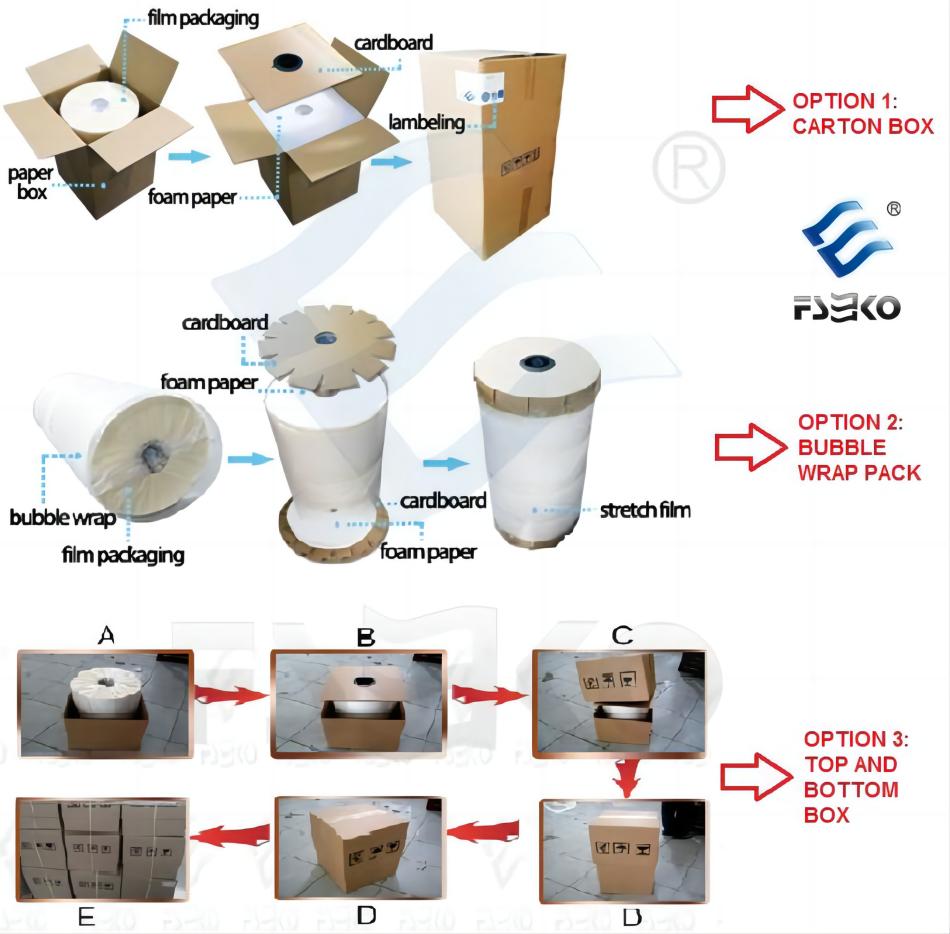

There are 3 types of packaging for thermal lamination film: Carton box, bubble wrap pack, top and bottom box.

Thermal lamination film product Q&A

1. What is thermal lamination film?

Thermal lamination film is widely utilized in the printing and packaging field for protecting and improving the appearance of printed items. It is a multi - layer film, typically consisting of a base film and an adhesive layer (EKO uses EVA). During the lamination process, the adhesive layer is activated by heat, resulting in a firm bond between the film and the printed material.

2. How to use thermal lamination film?

Using thermal lamination film is a relatively simple process. Here are the general steps:

a) Prepare the printing material: Make sure the printing material is clean and free of any dust or debris.

b) Setting up your laminator: Follow the instructions that came with your laminator for proper setup. Adjust the temperature and speed settings according to the type of thermal lamination film you are using.

c) Loading Film: Place one or more rolls of hot laminating film on the laminator, making sure they are properly aligned.

d) Feed the printed material: Insert the printed material into the laminator, making sure it is aligned with the film.

e) Start the lamination process: Start the machine to start the lamination process. Heat and pressure from the machine will activate the adhesive layer, bonding the film to the printed material. Make sure the laminate comes out the other end of the machine smoothly.

f) Trim excess film: After lamination is complete, use a cutting tool or trimmer to trim excess film from the edges of the laminate, if necessary.

3. How many types of thermal lamination film does EKO have?

BOPP thermal lamination film

PET thermal lamination film

Digital super sticky thermal lamination film series

Thermal lamination film for inkjet printing series

Low temperature thermal lamination film

Soft touch thermal lamination film

Anti-scratch thermal lamination film

BOPP thermal lamination film for food preservation card

PET metalized thermal lamination film

Embossing thermal lamination film

etc.

For other products using in printing industry, there are digital hot sleeking foil, DTF film & DTF paper, thermal transfer ribbons, etc.

FAQ

The normal laminating pouch film and sticky-back laminating pouch film are both designed for photos, certificates, and other documents for protecting purpose. They all come in a variety of sizes and thicknesses.

Sticky-back laminating pouch film is with self adhesive backing which is different from the normal one, it can be stuck to the smooth surface and transferable. After tearing off, no sticky residue. There are removable backing and ordinary backing versions for your choice, you can choose it on-demand.

It can be stuck to the smooth surface, like door, window, glass wall, tiled wall, etc.