About thermal lamination film

What is thermal lamination film?

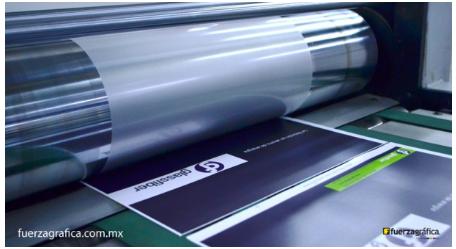

Thermal lamination film is pre coating on the plastic film with glue. And then heated and laminate with paper printing.

Comparing with traditional coating film, thermal lamination film is easier to operate, none solvent pollutions, and health for workers. It is glossier and can keep for a longer time, to protect the printing color from change. It is no wrinkles, bubbles, or desquamates, which is suitable for any ordinary hot lamination machines.

Equipment for laminating film:

Dry and wet laminating machine, with heating function

Temperature: normal prints:90~100℃; special prints: 100~110℃

Thermal film advantages

With high transparency, and it can get a nice appearance, as well as protecting the prints after laminating.

It was no bubble, wrinkle or desquamate after laminating;

Easy to operate the laminating machines, which can low down the cost.

Wide product application field, suitable for advertising prints, digital prints.

Meet the environmental requirements of the occident countries, it has been widely used all over the world

No solvent pollution during the production, it is environmental-friendly and healthy for the production and usage.

Suitable for any ordinary hot laminating machines.

Speed, temperature and pressure are the key factors of pre-coating composite process

① The adhesive used for pre-coating is EVA glue hot melt adhesive. Therefore, strictly controlling the temperature is the primary key of the thermal lamination film.

② Because the surface of the paper is not very flat. And the viscous hot melt adhesive will fully wet the surface of the paper print in the process of driving away the air on the print only under the action of pressure.

③ As the speed of the laminating machine increases, the hot pressing force decreases, which makes the composite effect worse. If the operation speed is too fast and the bonding is not firm, there will be fog or even blistering.

If you need some sample for your test , please contact us feel free admin@fseko.com.

Post time: Feb-15-2022