Thermal lamination film as a convenient and economical product, more and more people start using it. EKO as Chinese leading thermal lamination film manufacturer, we launch lots of new products these years such as digital soft touch thermal lamination film, digital anti-scratch thermal lamination film, sticky-back thermal lamination film, non-plastic thermal lamination film, etc. These new products attract many customers.

Before shipping, how we pack the products? There are 3 types of packaging way we usually use to meet the needs of different customers.

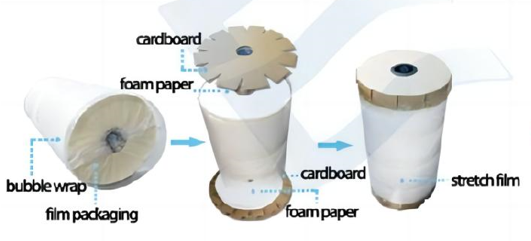

Foam+stretch film

Covering the surface of the product with a layer of foam and then wraps it with stretch film, which can effectively protect the surface of the product from scratches and damage. This packaging way can reduce the use of packaging materials and lower the packing expense. But its protective capability is not as strong as the other two packaging methods, so we usually use it for domestic order.

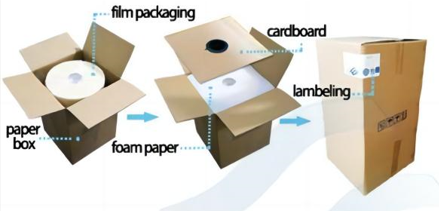

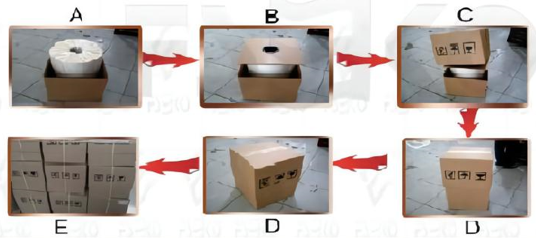

Top and bottom box

Top and bottom box is a traditional but classic packaging form, suitable for products of various specifications. Its advantage is that it has a solid structure, is easy to stack and carry, and can effectively protect products from extrusion and collision during transportation. In addition, in order to reinforce the box, we will also make a crossed tape outside it.

Carton box

Carton box is a kind of package that need to be customized according to the size of film. It has good load-bearing capacity and protective properties as same as top and bottom box, but carton box is better looking than it.

Three different packaging methods have their own advantages. Customers can choose the right one according to their needs~

Post time: Jul-09-2024