DTF Paper For Textile

Product Description

DTF papers used in the direct-to-film printing process are specifically designed to be compatible with DTF printers. Its primary function is to transfer designs on films onto a variety of surfaces, including textiles, clothing, and other materials.

DTF paper and DTF film are both use in DTF printing process. The biggest difference is DTF film is made of plastic film while DTF paper is made of paper, paper is much more environmentally friendly than film. When using the DTF paper, we don't need to change printing equipment, we can use the same printing machine as DTF film.

EKO is a company engaged in the R &D, production and sales of thermal lamination film for over 20 years in Foshan since 1999, which is one of the thermal lamination film industry standard setter. We provide a variety of products to meet the needs of various industries such as BOPP thermal lamination film, PET thermal lamination film, super sticky thermal lamination film, anti-scratch thermal lamination film, digital hot sleeking film, etc.

Advantages

1. Affordable and Cost-Effective

Introducing the DTF paper as a new printing material to address the issue of high supply costs for our customers. As a result, it is significantly more economical compared to traditional DTF film. If you’re aiming for substantial profits in the digital printing industry without requiring large initial investments, consider EKO DTF paper as a long-term supply solution.

2. Eco-Friendly and Safe

The EKO DTF transfer paper is crafted from recyclable materials, posing no harm to the environment as it naturally decomposes. With DTF paper, environmental concerns are no longer a worry.

3. User-Friendly and Versatile

Ideal for transfer printing, ironing, various clothing transfer trademarks, transfer patterns, wash labels, personalized DTF printing, and more. It is suitable for DTF film printing on various textiles, including ready-to-wear T-shirts, cut pieces, shirt fabrics.

4. Consistent Quality and Outstanding Performance

EKO DTF paper exhibits resistance to high temperatures, wrinkles, and friction. Not only is it lightweight and eco-friendly, but it also delivers superior quality and excellent color printing performance. No need for engraving, hollowing out, or elimination.

Specification

| Specification | Product name | DTF paper |

| Material | Paper | |

| Thickness | 75mic | |

| Weight | 70g/㎡ | |

| Width range | 300mm, 310mm, 320mm, 600mm, can be customized | |

| Length range | 100m, 200m, 300m, can be customized | |

| Heat transfer temp. | 160℃ | |

| Heat press time | 5~8 seconds, hot-peel | |

| Application | clothes pillowslip bed sheet decorative fabric suitable for most textiles |

After sales service

Please let us know if there's any problem after receiving, we will pass them to our professional technical support and will try to help you to solve.

If the problems are still unresolved, you can send us some samples(the film, your products which have problems with using the film). Our professional technical inspector will check and find the problems.

Storage indication

Please keep the films indoor with cool and dry environment. Avoid high temp, moist, fire and direct sunlight.

It's best used within 1 year.

Packaging

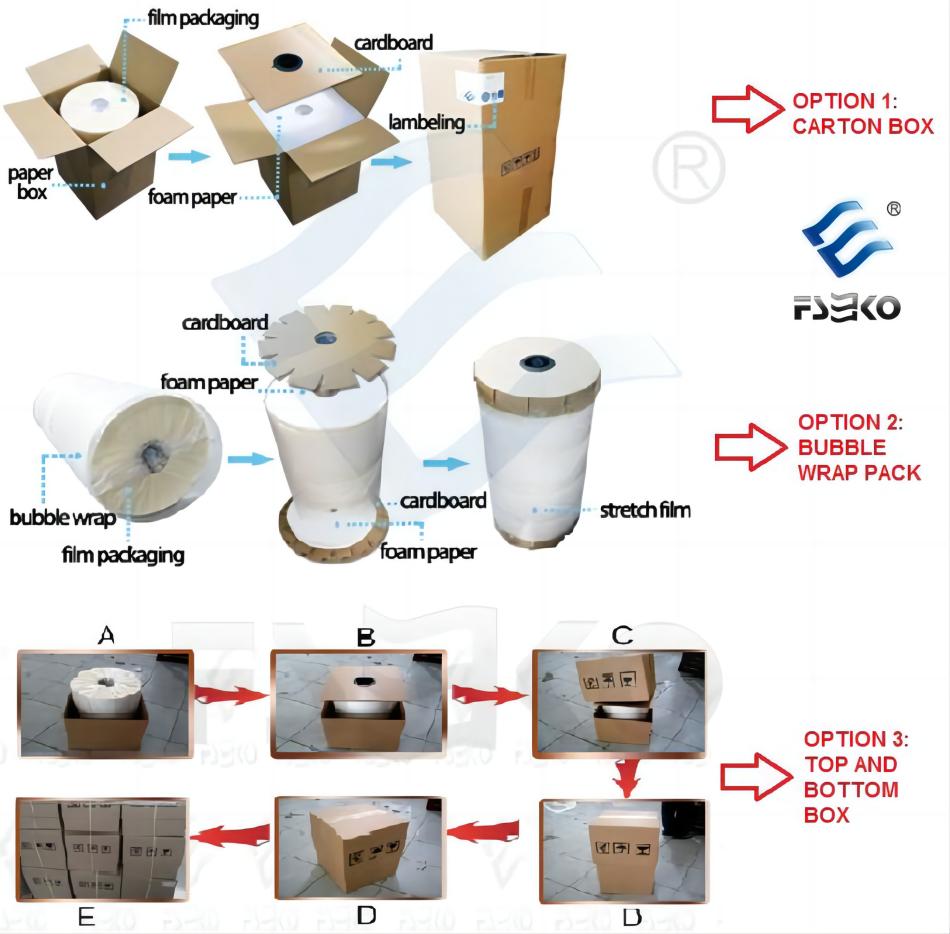

There are 3 types of packaging for thermal lamination film: Carton box, bubble wrap pack, top and bottom box.

Q&A

DTF paper and DTF film are both use in DTF printing process. The biggest difference is DTF film is made of plastic film while DTF paper is made of paper, paper is much more environmentally friendly than film. When using the DTF paper, we don't need to change printing equipment, we can use the same printing machine as DTF film.